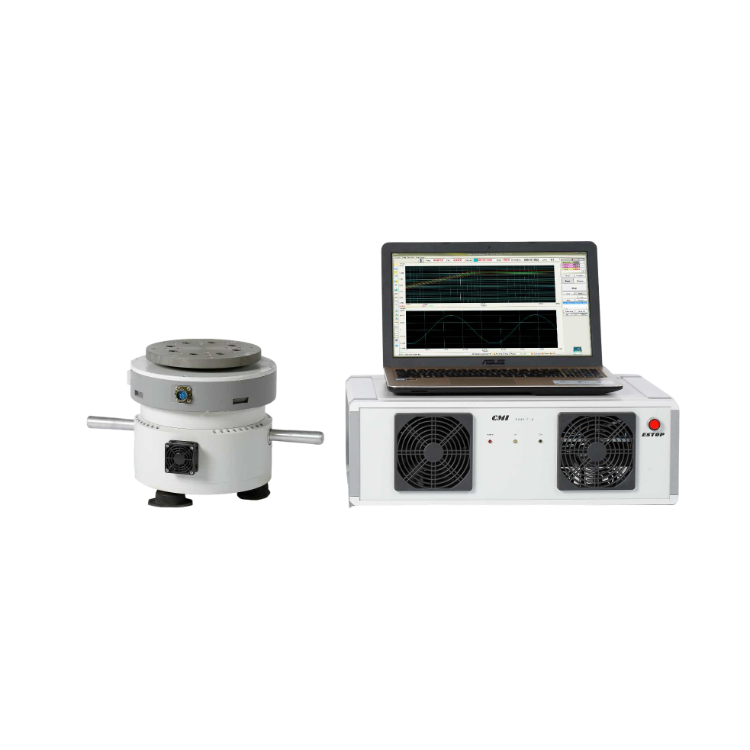

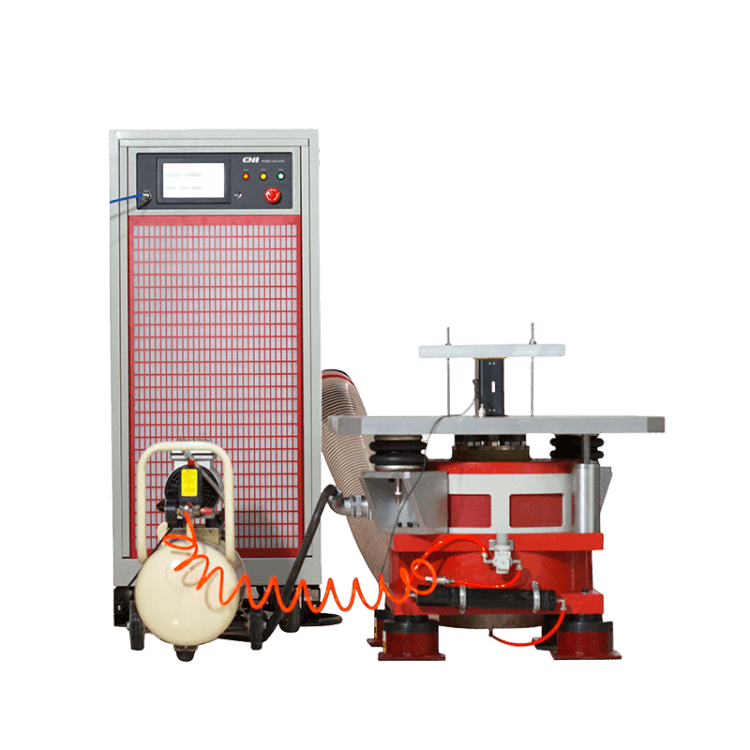

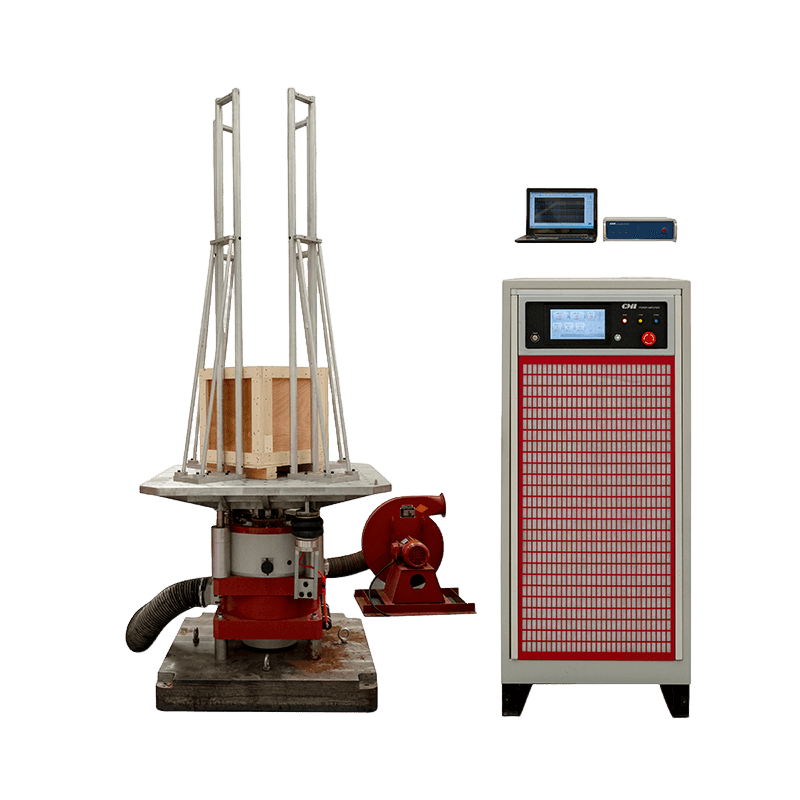

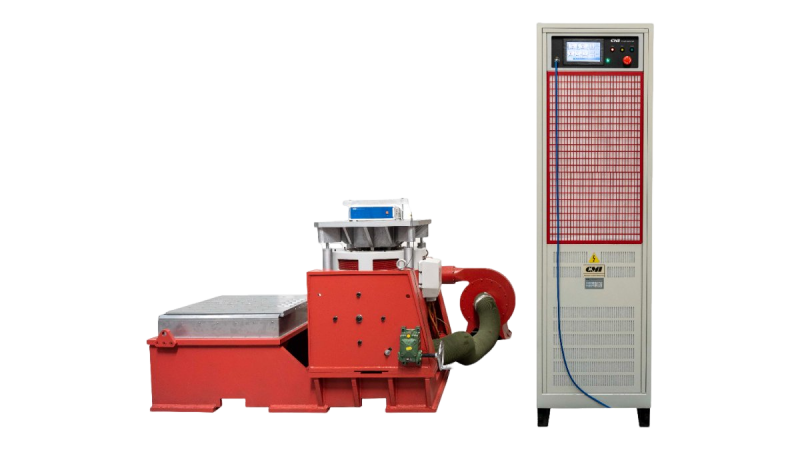

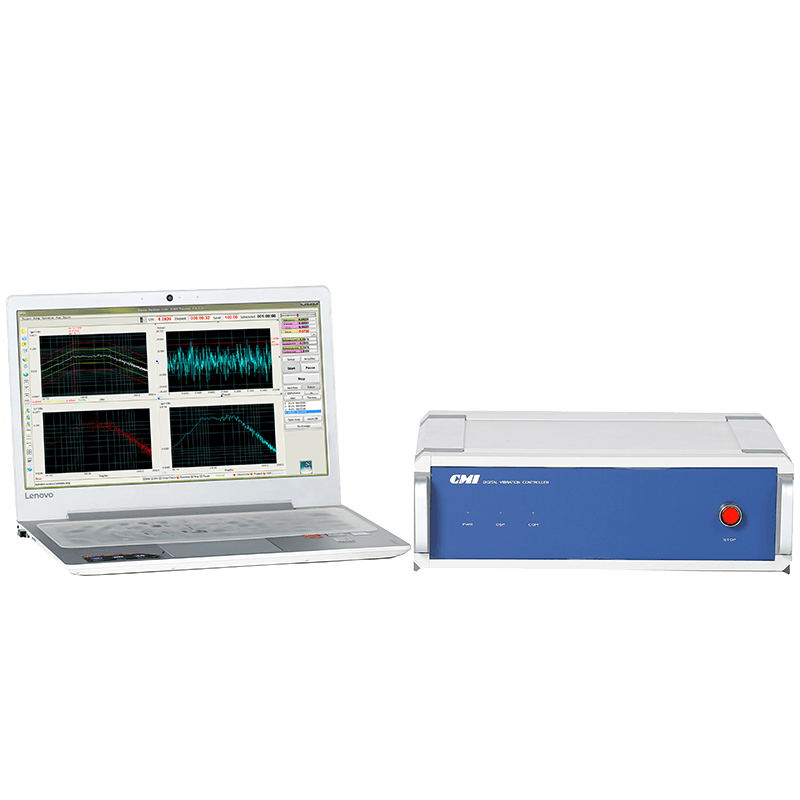

At CMI, we offer a comprehensive range of vibration testing equipment that is perfectly designed to ensure the integrity and reliability of your products. Our portfolio includes advanced electrodynamic shakers, controller. We have the expertise to tailor our solutions to your specific needs. With our cutting-edge technology and customizable options, you can trust CMI to provide you with the most effective vibration test equipment to meet your requirements.